Nā moena fiber aniani

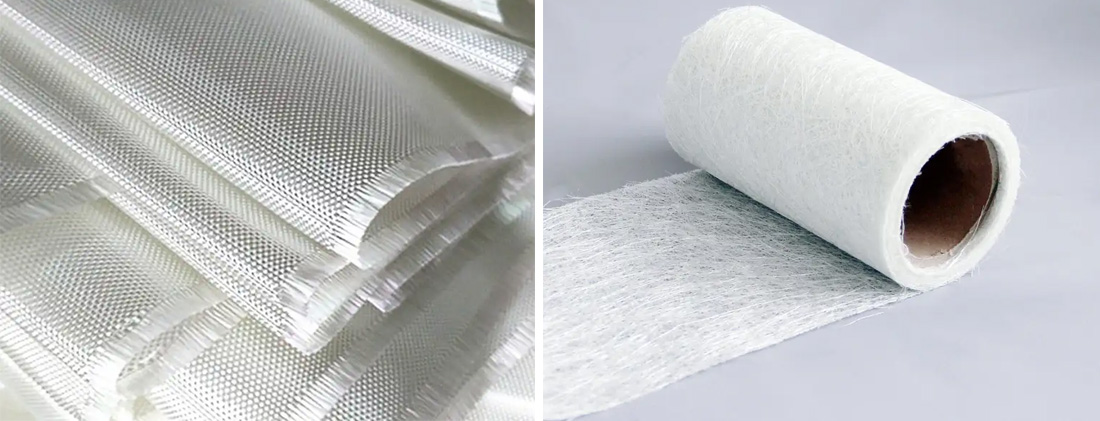

1.Moena Kaula i ʻoki ʻia (CSM)Ke hele wāwae nei ka fiber aniani(i kekahi manawa he roving hoʻomau) ua ʻoki ʻia i loko o 50mm ka lōʻihi, kau ʻia ma ke ʻano maʻamau akā like ma luna o kahi kāʻei ʻupena conveyor. A laila hoʻopili ʻia kahi mea hoʻopaʻa emulsion, a i ʻole e kāpīpī ʻia kahi mea hoʻopaʻa pauka, a hoʻomehana ʻia ka mea a hoʻōla ʻia e hana i ka moena kaula i ʻoki ʻia. Hoʻohana nui ʻia ʻo CSM i ka waiho lima ʻana, ka hana panel hoʻomau, ka hoʻoheheʻe make i hoʻohālikelike ʻia, a me nā kaʻina hana SMC (Sheet Molding Compound). ʻO nā koi maikaʻi no CSM:

- Ke kaumaha like o ka ʻāpana ma ka laulā.

- Ka hoʻolaha like ʻana o nā kaula i ʻokiʻoki ʻia ma luna o ka ʻili moena me ka ʻole o nā hakahaka nui, a me ka hoʻolaha like ʻana o nā mea hoʻopaʻa.

- Ikaika moena maloʻo waena.

- Nā waiwai hoʻomaʻū a komo maikaʻi loa i ka resin.

2.Moena Filament Hoʻomau (CFM)Hoʻomoe ʻia nā filament fiber aniani hoʻomau i hana ʻia i ka wā o ke kaʻina hana kaha kiʻi a i ʻole e wehe ʻia mai nā ʻeke roving i loko o ke ʻano helu ʻewalu ma luna o kahi kāʻei mesh e neʻe mau ana a hoʻopaʻa ʻia me kahi mea hoʻopaʻa pauka. ʻOiai he mau kaʻina hana nā fibers i loko o CFM, hāʻawi lākou i ka hoʻoikaika maikaʻi i nā mea composite ma mua o CSM. Hoʻohana nui ʻia ia i nā kaʻina hana pultrusion, RTM (Resin Transfer Molding), pressure bag molding, a me GMT (Glass Mat Reinforced Thermoplastics).

3.Moena ʻiliʻO ka maʻamau, pono nā huahana FRP (Fiber Reinforced Plastic) i kahi papa ʻili momona i ka resin, kahi i hoʻokō pinepine ʻia me ka hoʻohana ʻana i ka moena ʻili aniani medium-alkali (C-glass). Ma muli o ka hana ʻia ʻana o kēia moena mai ke aniani C, hāʻawi ia i ka FRP me ke kūpaʻa kemika, ʻoi aku ka kūpaʻa waikawa. Eia kekahi, ma muli o kona lahilahi a me ke anawaena fiber maikaʻi, hiki iā ia ke omo i ka resin hou aʻe e hana i kahi papa momona i ka resin, e uhi ana i ke ʻano o nā mea hoʻoikaika fiber aniani (e like me ka ulana roving) a lawelawe ma ke ʻano he hoʻopau ʻili.

4.Moena KuilaHiki ke hoʻokaʻawale ʻia i loko o ka moena ʻokiʻoki fiber needled a me ka moena hoʻomau filament needled.

- Moena i ʻoki ʻia me ka nila fiberHana ʻia ma ke ʻoki ʻana i ke aniani fiber e holo ana i 50mm ka lōʻihi, e kau ana iā lākou ma luna o kahi substrate i kau mua ʻia ma luna o kahi kāʻei conveyor, a laila e kui iā ia me nā nila barbed. Hoʻokuke nā nila i nā fibers i ʻoki ʻia i loko o ka substrate, a lawe mai nā barbs i kekahi mau fibers i luna, e hana ana i kahi ʻano ʻekolu-dimensional. Hiki i ka substrate i hoʻohana ʻia ke lilo i lole ulana palupalu o ke aniani a i ʻole nā fibers ʻē aʻe. Loaʻa i kēia ʻano moena nila kahi ʻano like me ka felt. ʻO kāna mau hoʻohana nui e pili ana i nā mea insulation thermal a me acoustic, nā mea lining, a me nā mea kānana. Hiki ke hoʻohana ʻia i ka hana FRP, akā ʻo ka FRP hopena he haʻahaʻa ka ikaika a me ka laulā noi palena.

- Moena Nila Filament HoʻomauHana ʻia ma ke kiola ʻana i nā filaments fiber aniani hoʻomau ma luna o kahi kāʻei mesh hoʻomau me ka hoʻohana ʻana i kahi mea hoʻolaha filament, a ukali ʻia e ke kui ʻana me kahi papa nila e hana i kahi moena me kahi ʻano fiber ʻekolu-dimensional i ulana ʻia. Hoʻohana nui ʻia kēia moena i ka hana ʻana o nā pepa thermoplastic i hoʻoikaika ʻia i ka fiber aniani.

5.Moena i humuhumu ʻiaHiki ke humuhumu ʻia nā olonā aniani i ʻoki ʻia mai 50mm a 60cm ka lōʻihi me kahi mīkini humuhumu e hana i kahi moena olonā i ʻoki ʻia a i ʻole kahi moena olonā lōʻihi. Hiki i ka mea mua ke pani i ka CSM i hoʻopaʻa ʻia me ka mea hoʻopaʻa maʻamau i kekahi mau hana, a hiki i ka mea hope, i kekahi ʻano, ke pani i ka CFM. ʻO kā lākou mau pono maʻamau ka nele o nā mea hoʻopaʻa, ka pale ʻana i ka haumia i ka wā o ka hana ʻana, ka hana hoʻopili resin maikaʻi, a me ke kumukūʻai haʻahaʻa.

Nā lole olonā aniani

Hoʻolauna kēia i nā lole fiber aniani like ʻole i ulana ʻia mainā olonā aniani.

1.Lole AnianiUa māhele ʻia ka lole aniani i hana ʻia ma Kina i nā ʻano alkali-free (E-aniani) a me ka medium-alkali (C-aniani); hoʻohana ka hapa nui o nā hana haole i ka lole aniani E-ANIANI alkali-free. Hoʻohana nui ʻia ka lole aniani e hana i nā laminates insulating uila like ʻole, nā papa kaapuni i paʻi ʻia, nā kino kaʻa, nā pahu mālama, nā waʻa, nā ʻōmole, a pēlā aku. Hoʻohana nui ʻia ka lole aniani medium-alkali e hana i nā lole ʻūlū i uhi ʻia i ka plastic a no nā noi pale i ka corrosion. Hoʻoholo ʻia nā ʻano o ka lole e nā waiwai fiber, ka nui o ka warp a me ka weft, ke ʻano o ka hilo, a me ke ʻano ulana. Hoʻoholo ʻia ka nui o ka warp a me ka weft e ke ʻano o ka hilo a me ke ʻano ulana. ʻO ka hui pū ʻana o ka nui o ka warp a me ka weft a me ke ʻano hilo e hoʻoholo ai i nā ʻano kino o ka lole, e like me ke kaumaha, ka mānoanoa, a me ka ikaika haki. ʻElima mau ʻano ulana kumu: plain (like me ka ulana roving), twill (ma ke ʻano maʻamau ± 45°), satin (like me ka lole unidirectional), leno (ulanana nui no ka ʻupena fiber aniani), a me matts (like me ka lole oxford).

2.Lipine ʻōwili anianiUa māhele ʻia i loko o ka lipine ʻoi ulana (ʻoi selvage) a me ka lipine ʻoi non-woven (ʻoi frayed). ʻO ke ʻano ulana nui he maʻemaʻe. Hoʻohana pinepine ʻia ka lipine fiber aniani alkali-free e hana i nā ʻāpana lako uila e pono ai ka ikaika kiʻekiʻe a me nā waiwai dielectric maikaʻi.

3.ʻO ka lole ʻaoʻao hoʻokahi o ke aniani fiber

- ʻO ka lole Warp Unidirectionalhe lole ulana satin haʻihaʻi ʻehā-hao a i ʻole satin ʻau lōʻihi i ulana ʻia me nā olonā warp coarse a me nā olonā weft maikaʻi. ʻO kona ʻano he ikaika kiʻekiʻe ma ke kuhikuhi warp (0°).

- Aia pū kekahiʻO ka lole ulana Unidirectional fiber aniani, loaʻa i nā ʻano ulana warp a me nā ʻano ulana. Hōʻike ʻia ia e nā olonā weft coarse a me nā olonā warp maikaʻi, me nā olonā fiber aniani i kuhikuhi nui ʻia ma ke kuhikuhi weft, e hāʻawi ana i ka ikaika kiʻekiʻe ma ke kuhikuhi weft (90°).

4.ʻO ka lole 3D fiber aniani (lole stereoscopic)Pili nā lole 3D i nā lole planar. Ua ulu ko lākou mau hiʻohiʻona kūkulu mai hoʻokahi-dimensional a ʻelua-dimensional a i ʻekolu-dimensional, e hāʻawi ana i nā mea i hoʻohui ʻia i hoʻoikaika ʻia e lākou i ka pono maikaʻi a me ke kūlike, e hoʻomaikaʻi nui ana i ka ikaika shear interlaminar a me ka hoʻomanawanui anti-damage o nā composites. Ua hoʻomohala ʻia lākou e hoʻokō i nā pono kūikawā o nā ʻoihana aerospace, mokulele, mea kaua, a me ke kai, a ua hoʻonui ʻia kā lākou noi e hoʻokomo i nā kaʻa, nā mea haʻuki, a me nā lako lapaʻau. ʻElima mau māhele nui: nā lole 3D i ulana ʻia, nā lole 3D i ulana ʻia, nā lole 3D non-crimp orthogonal a me non-orthogonal, nā lole ulana 3D, a me nā ʻano lole 3D ʻē aʻe. ʻO nā ʻano o nā lole 3D e komo pū me ka poloka, columnar, tubular, hollow truncated cone, a me nā ʻāpana keʻa irregular variable-thickness.

5.Lole Preform Fiber Aniani (Lole i hoʻohālikelike ʻia)Ua like loa ke ʻano o nā lole preform me ke ʻano o ka huahana a lākou i manaʻo ai e hoʻoikaika, a pono e ulana ʻia ma nā looms i hoʻolaʻa ʻia. ʻO nā lole ʻano symmetrical e komo pū ana me: nā pāpale poepoe, nā cones, nā pāpale, nā lole dumbbell-shaped, a pēlā aku. Hiki nō hoʻi ke hana ʻia nā ʻano asymmetrical e like me nā pahu a me nā ʻili waʻa.

6.ʻO ka lole ʻiʻo fiberglass (lole humuhumu mānoanoa)ʻO ka lole koʻikoʻi he ʻelua papa lole like i hoʻopili ʻia e nā kaha lōʻihi kū pololei. Hiki i kona ʻano ʻoki ke ʻano huinakolu, huinahā, a i ʻole ka meli.

7.ʻO ka lole i hoʻopaʻa ʻia me ke olonā aniani (moena ulana a i ʻole moena ulana)He ʻokoʻa ia mai nā lole maʻamau a mai ke ʻano maʻamau o ka moena. Hoʻokumu ʻia ka lole i hoʻopaʻa ʻia me ke kuʻi ma ke kau ʻana i hoʻokahi papa o ka olonā warp a me hoʻokahi papa o ka olonā weft, a laila e humuhumu pū iā lākou e hana i lole. ʻO nā pono o nā lole i hoʻopaʻa ʻia me ke kuʻi:

- Hiki iā ia ke hoʻonui i ka ikaika tensile hope loa, ka ikaika anti-delamination ma lalo o ke kaomi, a me ka ikaika flexural o nā laminates FRP.

- Hoʻemi ia i ke kaumaha oNā huahana FRP.

- ʻO ka ʻili pālahalaha e hoʻomaʻamaʻa ai i ka ʻili FRP.

- Hoʻomaʻalahi ia i ka hana hoʻomoe lima a hoʻomaikaʻi i ka huahua hana. Hiki i kēia mea hoʻoikaika ke pani i ka CFM i ka FRP pultruded a me ka RTM, a hiki nō hoʻi ke pani i ka ulana roving i ka hana ʻana i nā paipu FRP i hoʻolei ʻia.

Ka manawa hoʻouna: ʻOkakopa-22-2025