ʻO ka hoʻohui ʻana i nā peʻa aniani hollow i nā huahana rubber hiki ke lawe mai i nā pono he nui:

1、Ka hoemi kaumaha

ʻO nā huahana Rubber e pili ana i ka māmā a me ke ala paʻa, ʻoi aku ka nui o ka noi ʻana o ka microbeads rubber soles, mai ka density maʻamau o 1.15g/cm³ a i ʻole, e hoʻohui i 5-8 mau ʻāpana o nā microbeads, hoʻemi ʻia i 1.0g/cm³ (i ʻike mau ʻia ʻo "floating on the water"), aia kekahi degere o nā mea kūʻai aku a i ʻole ka nui o ka microbeads. ʻo 0.85g/cm³ hoʻi, e hōʻemi nui ana i ka nui o ka pahu, nā kāmaʻa a me ke kūlana like ma mua o ka hoʻemi ʻana o ke kaumaha o 20% a i ʻole. I kēia manawa, ʻo kekahi mau mea kūʻai aku me ka mana R&D e hana i ka density 0.9 a i ʻole 0.85g/cm³ ma ka hoʻohui ʻana i nā microbeads, kahi e hōʻemi nui ai i ka nui o ka pahu, a e hoʻemi ʻia ke kaumaha o nā kāmaʻa ma kahi o 20% ma lalo o ke kūlana like ma mua.

2、Hoʻokuʻu wela

Hāʻawi ka hollow structure of hollow glass beads i nā pahu i kahi haʻahaʻa haʻahaʻa haʻahaʻa, no ka mea, hiki i kahi mea hoʻopihapiha hoʻopihapiha haʻahaʻa haʻahaʻa i hoʻohui ʻia i ka mea hao e hiki ke pāʻani i kahi hopena wela maikaʻi loa, e like me nā pads insulation thermal, thermal insulation boards a me nā huahana ʻē aʻe i hoʻohana ʻia.

3、Ka hoʻopaʻa leo a me ka hoʻohaʻahaʻa leo

I loko o nā pahu aniani ʻāwīwī he kinoea lahilahi, e hoʻonāwaliwali ʻia nā hawewe kani i kēia ʻāpana, i kahi nui o ka hoʻohui e pāʻani i kahi hopena maikaʻi loa o ke kani ʻana a me ka hoʻohaʻahaʻa leo.

4、Maikaʻi ke kūlana paʻa

He aniani me ka haʻahaʻa coefficient o ka hoʻonui ʻana i ka wela, ke kūpaʻa ʻana o ka nui i ka wā e hoʻokau ʻia ai i ka haʻalulu wela, i hoʻohui ʻia i ka mea hao e hāʻawi i ka huahana ʻoi aku ka maikaʻi.

Manaʻo no ka hoʻohana ʻana i ka hana ʻana:

ʻO 1, ʻo nā mea hana kaʻa kaʻa ka mea hoʻomaʻemaʻe maʻamau, opener, hoʻokahi-screw extruder, a me nā mea ʻē aʻe, no ka mea, ʻo nā beads he aniani mea paʻa no nā ʻāpana paʻa, ma ke ʻano o ka mechanical shear force e wāwahi ʻia, e nalowale nā pea i kāna hana kūikawā ma hope o ka haki ʻana.

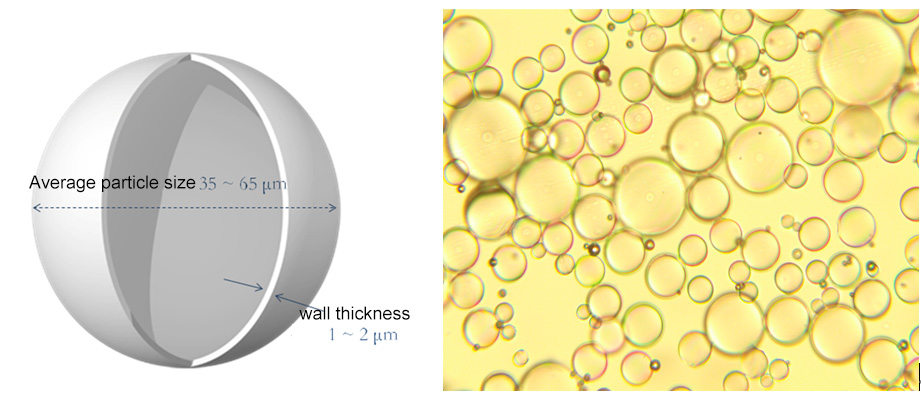

2, he mau hi'ohi'ona 'oko'a a me nā palena like 'ole nā pahu aniani hollow, e like me nā lako a me nā koi huahana e koho i nā huahana beads pono he mea ko'iko'i loa ia, paipai 'o St. Leite i ka ho'ohana 'ana i HL38, HL42, HL50, HS38, HS42 i nā huahana lā'au.

3, i ka wā e hoʻohana ai i ka mīkini hoʻomaʻemaʻe, aia kahi rotor ma ka ʻāʻī ʻōpala, ʻaʻole hiki ke pale ʻia nā beads e ka ikaika o ka ʻāʻī, no laila e hiki ke hoʻemi i ka manawa o nā beads i ka hoʻomaʻemaʻe ʻana, ua ʻōlelo ʻia e hoʻohui i ka hoʻomaʻemaʻe hope e hōʻoia i ka hiki ke hoʻopuehu ʻia nā pahu i hoʻohui ʻia i ka hoʻomaʻemaʻe 3-5min; i loko o ka mīkini hoʻomaʻemaʻe, ʻoi aku ka nui o ka hopena o ka roller spacing a me ka manawa hoʻomaʻemaʻe o ka ʻoki ʻana i nā pahu, ua ʻōlelo ʻia ʻaʻole e lōʻihi ka lōʻihi o ka roller spacing> 2mm, ka manawa hoʻomaʻemaʻe; He liʻiliʻi ka ikaika shear holoʻokoʻa o ka extruder screw hoʻokahi, ʻōlelo liʻiliʻi, liʻiliʻi ka hopena i nā microbeads, ʻōlelo ʻia e hoʻonui i ka mahana extrusion e 5 ℃, e hoʻemi i ka viscosity o ka mea i ʻoi aku ka maikaʻi i ka extrusion molding, e hoʻemi i ka microbeads haki.

Ka manawa hoʻouna: Iulai-21-2023